AIMEX III

AIMEX III Flexible Placement Platforms

The AIMEX III is designed for component flexibility, PCB flexibility and production flexibility.

Features

Production for Large Panels or Simultaneous Production of Two Models

The AIMEX III can support large panels up to 774 (L) x 710 (W) mm in size.

Simultaneous production of two different products is possible using our dual conveyor configuration machine. The AIMEX III also enables various production

methods and supports a wide range of panel sizes.

Supporting 0402 (01005") to 74 x 74 mm with one head

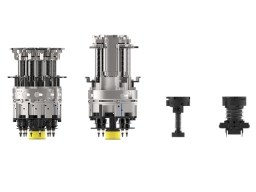

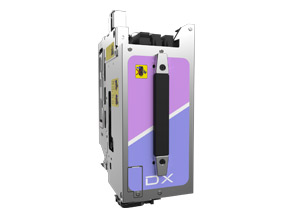

Our DX head exchanges the dedicated tool in one action depending on the part size, from small chips to large odd-form parts. Also, using wide range nozzles together provides further efficient placement.

DynaHead Dynamic Exchange

The AIMEX III offers dynamic exchange during production to the best tool for the job. Borderless production is made possible using the DynaHead to dynamically exchange between 12-nozzle, 4-nozzle and single nozzle tools.

Minimizing the changeover count

Changeover time can be reduced by performing MFU batch changeover and by the machine having up to 130 slots for feeders which makes it possible to load all of the required parts.

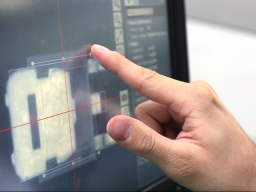

Ramping up production smoothly

Automatic data creation and on-machine editing using a large touchscreen panel work to support ramping up new production and quick response to sudden changes to programs.

Specifications

| Basic Specifications | ||

|---|---|---|

| PCB size(LXW) |

|

|

| Feeder capacity | Up to 130 (8 mm tape) | |

| PCB load time | 2.9 sec | |

|

Placing accuracy (Fiducial mark based referencing) |

H24G: +/-0.025 mm (Standard mode) / +/-0.038 mm (Productivity priority mode, under development) (3sigma) cpk≥1.00 H08M: +/-0.040 mm (3σ) cpk≥1.00 OF: +/-0.050 mm (3σ) cpk≥1.00 H02F: +/-0.025 mm (3σ) cpk≥1.00 H01: +/-0.030 mm (3σ) cpk≥1.00 |

|

| Machine dimensions | L: 1280mm, W: 2656mm, H: 1556mm | |

| Placing heads | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H24G | H08M | H02F | H01 | OF | |||||||

| Nozzle quantity | 24 | 8 | 2 | 1 | 1 (or 1 claw) |

||||||

| Throughput(cph) |

37,000 cph (Productivity priority mode, under development) 35,000 cph (Standard mode) |

13,000 | 7,300 | 4,200 | 3,000 | ||||||

| Part size (mm) |

03015 mm to 5 x 5 Height: Up to 2.0 mm |

0603 (0201") to 45 x 45 Height: Up to 13.0 mm |

1608 (0603") to 74 x 74 (32 x 180) Height: Up to 25.4 mm |

1608 (0603") to 74 x 74 (32 x 180) Height: Up to 38.1 mm |

|||||||

| Part presence check |

○ | ○ (H08MQ) |

○ | x | |||||||

| Parts supply |

Tape | ○ | ○ | ○ | ○ | ||||||

| Stick | x | ○ | ○ | ○ | |||||||

| Tray | x | ○ | ○ | ○ | |||||||

| DynaHead(DX) | ||||

|---|---|---|---|---|

| Nozzle quantity | 12 | 4 | 1 | |

| Throughput(cph) | 27,000 Parts presence function ON: 26,000 |

12,000 | 5,800 | |

| Part size (mm) |

0402 (01005") to 12.5 mm diagonally and Y is 7.5 mm or less Height: Up to 3.0 mm |

1608 (0603") to 15 x 15 Height: Up to 6.5 mm |

1608 (0603") to 74 x 74 (32 x 100) Height: Up to 25.4 mm |

|

|

Placing accuracy (Fiducial mark based referencing) |

+/-0.038 (+/-0.050) mm (3σ) cpk≥1.00 | +/-0.040 mm (3σ) cpk≥1.00 | +/-0.030 mm (3σ) cpk≥1.00 | |

| Part presence check |

o | x | o | |

| Parts supply |

Tape | o | o | o |

| Stick | x | o | o | |

| Tray | x | o | o | |

*Contact Fuji or sales agents for specific operating conditions and detailed specifications.