NEXIM

Nexim Software

Our flexible solution integrates seamlessly with your production environment and boosts productivity with wizard and macro-based automation.

Features

Production using data

Creating program data is very easy with Nexim and production schedules can be created automatically. Instructions for checking out parts and performing changeover are issued based on these created schedules and part resupply instructions are issued matching the machine operating conditions.

For this, production is performed by connecting the stages with data using Nexim.

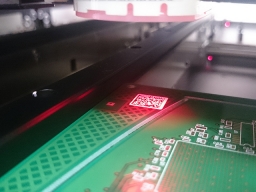

Production equipment automatically follows changes in work

By reading the marks and ID on panels in the production line, instructions to perform changeover are issued to machines from Nexim. The machines can perform changeover automatically right up to the positioning of backup pins, which allows production products to be changed without human intervention.

Predictive maintenance

Nexim does not just communicate with printers and placing machines, it can also connect to machines from other companies such as inspection machines and reflow machines. This allows for unified management of lines and from analyzing the information from inspection machines as well as placing machines, preventive maintenance can be performed before defects occur.

Learn fast, act quickly

When production is slow and when the operation rate is depreciating, it is very important to know about these kinds of problems and react quickly in order to keep quality and productivity high. When thresholds for delays in production and productivity are set in Nexim, this information can be sent to an email address to notify the operator about the issue so information that needs to be known about is known quickly.