AUTOMATE NOZZLE CLEANING

Automate Nozzle Cleaning, Inspection, and Setting - Smart Nozzle Cleaner

Management of nozzles is vital for placement quality control, as they directly contact electrical parts. With increased product variations due to diversified customers' needs, the manufacturing industry is accelerating customization. This has resulted in an increase in the quantity and types of nozzles used for part handling. On top of that, the recent trend of miniaturization of electrical parts requires more time and effort to handle and maintain nozzles.

To solve this issue, we are introducing Smart Nozzle Cleaner as a tool that allows operators to be free from such maintenance work and time while effectively using the required quantity of nozzles in a timely manner.

In addition to cleaning nozzles, Smart Nozzle Cleaners can facilitate nozzle distribution optimal for production schedules that change on a daily basis by performing a variety of inspections, visualizing the results, and managing traceability, contributing the improvement of QCD in the placement processes.

Easy operation

Smart Nozzle Cleaners provide easy operation without special operation and tools just by setting nozzle stations used in the placement machine to the Smart Nozzle Cleaner and selecting the menu displayed on the operation panel.

Operators only have to select the menu item that suits their purpose to perform maintenance of nozzles.

Function examples

- Clean and dry

- Inspections (vision processing for inside and outside nozzle surfaces, stuck nozzles, flow rate)

- Stocker operation

- Next production preparation

Operation example

With the push of a button in exchange operation mode (next production preparation), nozzles required for the next production are automatically prepared in the nozzle station. Operators merely have to push a button to start cleaning before going home, and cleaning of all nozzles will be completed before staff come in the next day.

This enables operators to spend the time usually devoted to cleaning nozzles toward other work during work hours.

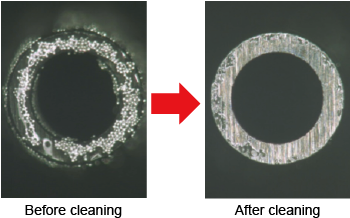

Guarantee stable cleaning results

Cleaning delicate nozzles by hand causes variations in the resulting nozzle condition after cleaning, and requires skill to do it right.

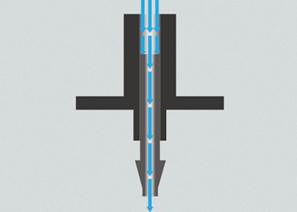

Smart Nozzle Cleaners clean nozzles using ultra-pure water, leading to stable cleaning results. In addition, nozzles will not be damaged due to interference between them during cleaning because they are automatically set at equal intervals.

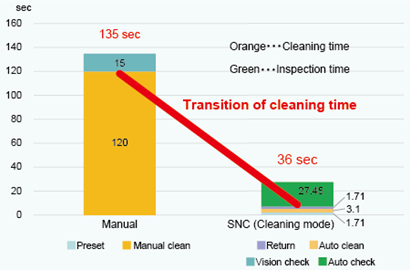

The cleaning time is 1/3 that of manual cleaning

The maintenance time for one nozzle (includes inspection time) will be reduced to one-third or less compared to manual cleaning.

The entire process from cleaning to drying and inspection is completely automated without relying on the skills of operators, thereby eliminating unevenness in work time.

Maintenance time per nozzle

(including inspection time)

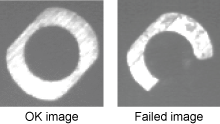

Accurate inspection and traceability management

Smart Nozzle Cleaners perform the following inspections and select nozzles usable for production.

Checks the 2D code reading capability

Checks whether the 2D codes printed on nozzles can be read.

Sliding inspection (mN, %)

Measures the pressure by contacting a nozzle to the load cell.

Tip inspection

Performs vision processing for the condition of the nozzle tip and checks for foreign matter and for chipped nozzles.

Flow inspection (L/min)

Measures the flow rate of nozzles to check for nozzle blockages.

Inspection results are recorded for each nozzle ID. If any inspection results in an error, nozzles with errors are sorted by defect cause and ejected.

More than 1,000 nozzles can be stocked

Smart Nozzle Cleaners have a large nozzle storage capacity. You can store over 1,000 nozzles in a unit.

Smart Nozzle Cleaners are equipped with stockers that can store nozzles not being used for production, and also automatically supply nozzles required for production to the nozzle station.

Automatically set the nozzles required for the next production

Linking to the Fuji host system (such as Fuji Flexa and Nexim) allows the nozzles that are to be used for the next production to be set in nozzle stations based on the setup information from the job.

Nozzles that fail an inspection are ejected as defective nozzles, which prevents issues caused by defective nozzles being used such as line stoppages and production defects, resulting in stable production.