CHANGEOVER SSS

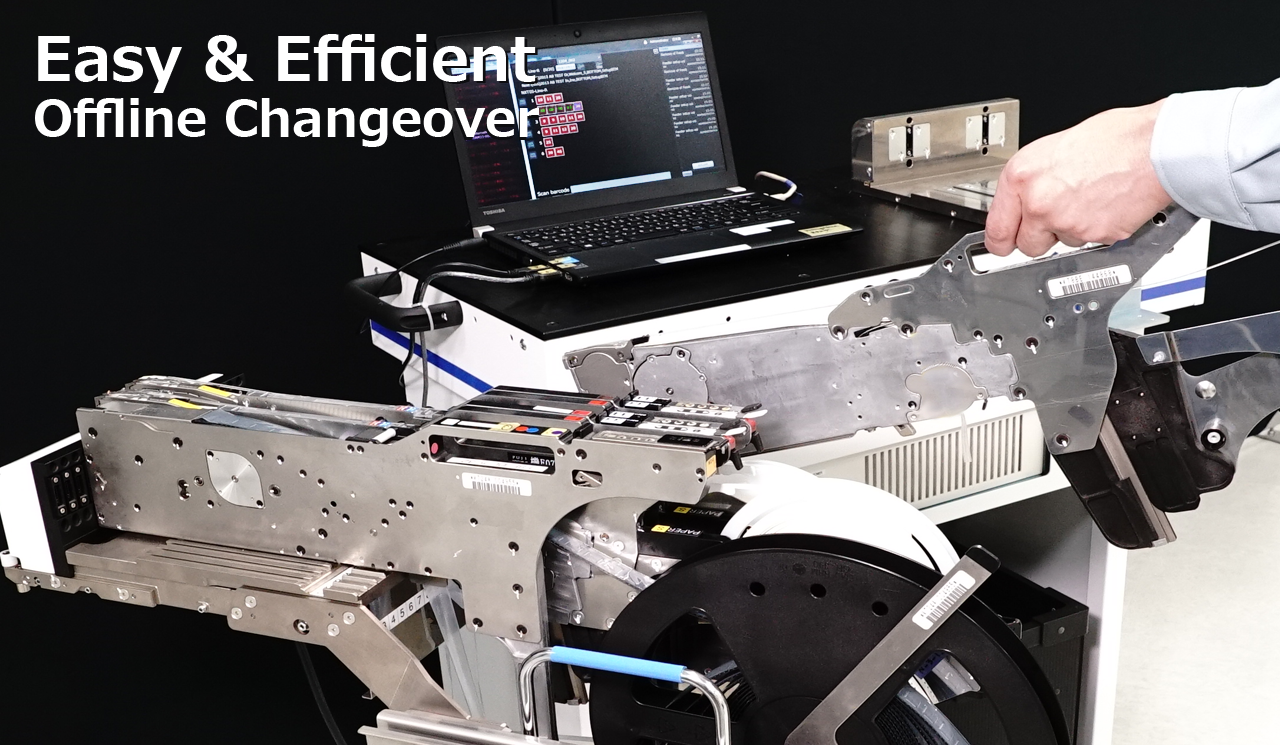

Offline Changeover With Smart Setup Station

Performing changeover work offline using the "external changeover" method for the next production while the current production is being performed is an effective way to minimize the length of time production is stopped because of changeover. The Smart Setup Station is a unit specifically designed for performing this offline changeover work efficiently. By using a Smart Setup Station, operators can perform the required offline changeover work accurately without hesitation.

Guidance for part setting positions and what work has already been completed is given using colors.

It is easy to visually check where to set feeders and what work has been completed. This makes it possible to accurately set parts in positions while operating within a digital environment.

Halve the time for collecting parts

It is possible to check the locations of required parts just by selecting the applicable work order. This makes it possible to halve the time for collecting parts*.

*: It is necessary to specify area management in Nexim based on our investigations.

Check the destination based on the unit ID

When you have multiple prepared feeder pallets and multi feeder units (feeder pallets (NXT III series) or multi feeder units (AIMEX III series) that support connecting to Nexim), guidance can be given for which line and machine to set that item by scanning the ID barcode of that item.