RELIABLE VISION PROCESSING

Easily create reliable vision processing data in a short time - Auto Shape Generator

When creating production programs on placement machines, approximately 80% (Note 1) of the work is related to creating vision processing data. Creating data for package parts with multiple leads and bumps is a very difficult and time-consuming task. If vision processing data is not properly set, it can cause losses such as misalignment and machine stoppage due to part recognition errors, so this work is extremely important for ensuring quality.

However, the volume of new programs is on the rise as the number of products to be produced increases due to the diversification of market needs. In addition, in order to shorten the lead time to ramping up production there is a need to reduce the time required to create programs, and the workload is becoming heavier and heavier.

We are pleased to introduce Auto Shape Generator, an application that solves the problems associated with creating such vision processing data.

Note 1: Investigated at Fuji

Auto Shape Generator features

- Anyone can quickly create accurate vision processing data

- Create data offline with a dedicated camera stand

- Immediately respond to vision processing errors during production

1. Anyone can quickly create accurate vision processing data

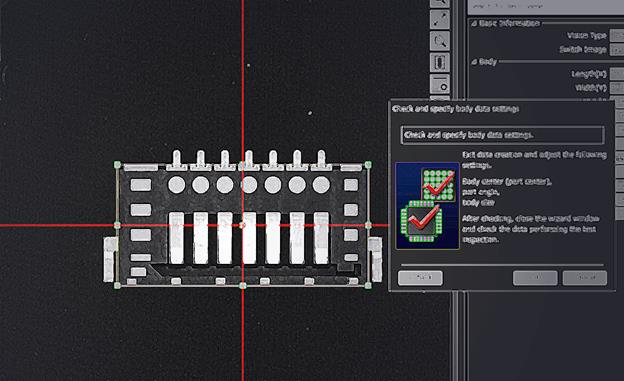

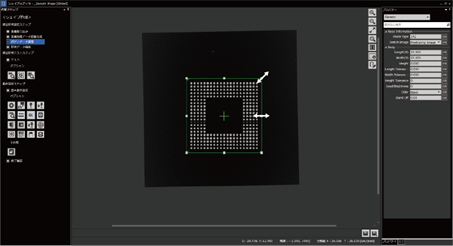

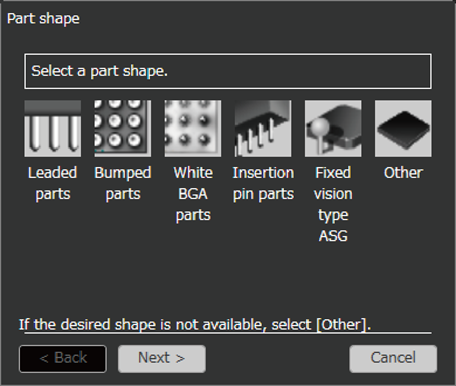

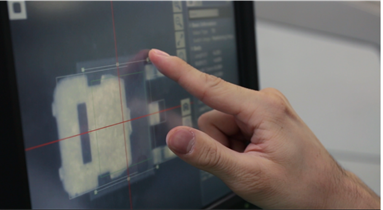

It is easy to create data by selecting items from the wizard type menu while using part images taken on the placement machine. The AI system not only identifies the body shape but also identifies bumps and leads on package parts so you can create accurate shape data. This is especially effective in creating irregularly arranged bump data.

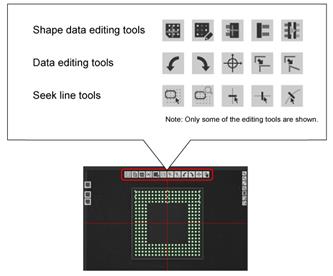

Even if parts are too complicated to create data automatically, it is possible to edit data using shape data that matches features in the image. It is possible to shorten the time it takes to create vision processing data for 90% or more of the parts available on the market (Note 2) by using Auto Shape Generator and shape data.

Note 2: Investigated at Fuji

2. Create data offline with a dedicated camera stand

By using a dedicated camera stand, it is possible to create data offline without stopping production. The camera stand for acquiring images of parts is equipped with the same camera and algorithms as the placement machine, which allows vision processing tests to be performed. This helps avoid machine stops due to vision processing errors at the start of mass production.

Note: A separate VPDplus license is required.

3. Immediately respond to vision processing errors during production

There are cases in which vision processing errors occur due to variations between part lots after starting production. For such cases, it is possible to quickly recover and restart production at the machine by changing the vision processing data based on part images acquired at the machine.

AIMEX III, AIMEX IIIc (can edit data at a line computer for NXT III and NXT IIIc)

In the midst of difficulties in securing personnel, Auto Shape Generator contributes to both the promotion of multi-skilled personnel and the reduction of lead time for ramping up production. You can see demonstrations of this unit in action in Fuji showrooms.

Please contact us for more information about our products or to visit our showrooms.