SMART SETUP STATIONS

Introduction of smart setup stations that simplify external setup work without waste

As market needs diversify, manufacturing sites are required to realize mass customization that realizes QCD at the same level as mass production. However, in the field of multi-product production, which frequently changes models, the decrease in production efficiency due to the increase in the number of setup changes is a major issue.

In order to shorten the setup change time at many production sites, feeder installation work is externally installed, and a bulk replacement method using feeder replacement trucks is adopted. However, the outer setup work is very delicate and time-consuming, with many tasks involving confirmation from parts to feeder mount. It is also a difficult process to schedule because it is highly dependent on people and workers have different working hours.

We introduce the support unit "Smart Setup Station" that solves these problems related to external setup work.

Features of smart setup stations

- 1. Automatically wind up only unnecessary parts

- 2. Guide the position of the feeder

- 3. Guide the position of the feeder pallet /MFU

- * It is used in cooperation with the external setup replacement function of the integrated production system Nexim.

- * Feeder pallets (NXT III series) and MFU (AIMEX III series) with communication function with Nexim are required.

1. Automatically wind up only unnecessary parts

When starting the outer setup work, the feeder pallet /MFU is equipped with parts used in the previous production. First of all, it is necessary to remove parts that are not scheduled to be used from among them, but removing unnecessary parts one by one while looking at the setup change list is very time-time.

For external setup work with smart setup stations, you can leave the parts that you want to continue using and automatically wind up only parts that you do not plan to use. You can reduce work man-hours by eliminating the need to review the setup list.

- * Operation settings must be performed in Nexim.

- * Please contact us for the target tape.

2. Guide the position of the feeder

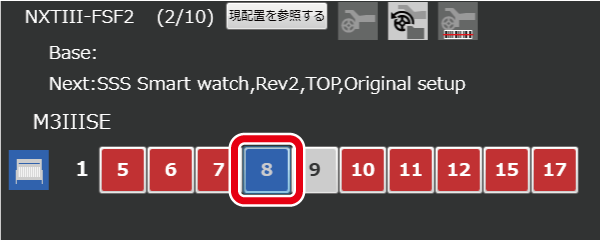

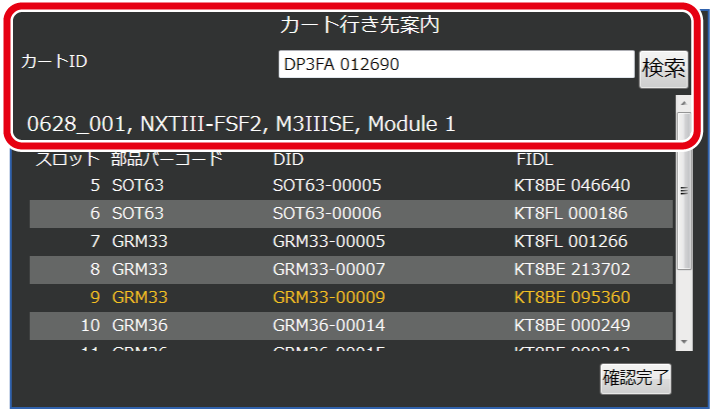

After loading the part into the feeder, Nexim will guide you to the feeder pallet/MFU when you scan the part's ID. When the feeder is installed in the guided position, the slot number displayed on the Nexim monitor changes color and you can confirm that the installation is complete.

The installation position and the completion can be visually confirmed by the change of color, so you can perform accurate work without hesitation.

Guide the installed position

Installion completed

3. Guide the position of the feeder pallet /MFU

By scanning the ID barcode of the ready feeder pallet/MFU, you can check the line and equipment to be installed. In addition, if the time to the inner setup is long after the outer setup is completed, and you want to check whether the feeder pallet / MFU is moved before installing it in the device, you can easily check by connecting the feeder pallet / MFU to the smart setup station and selecting the work menu.

Smart setup station that eliminates waste of external setup work and enables accurate work without hesitation. You can watch demonstrations using actual machines in fuji's showroom.

Please feel free to contact us for more information.