SMARTFAB

Features

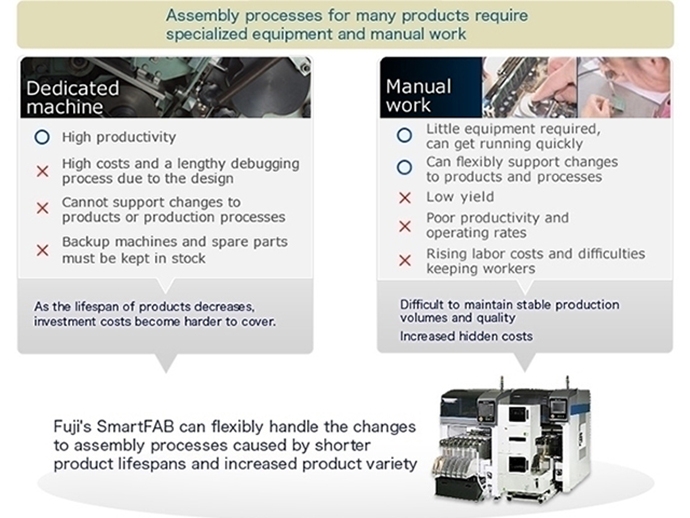

Current problems in assembly processes

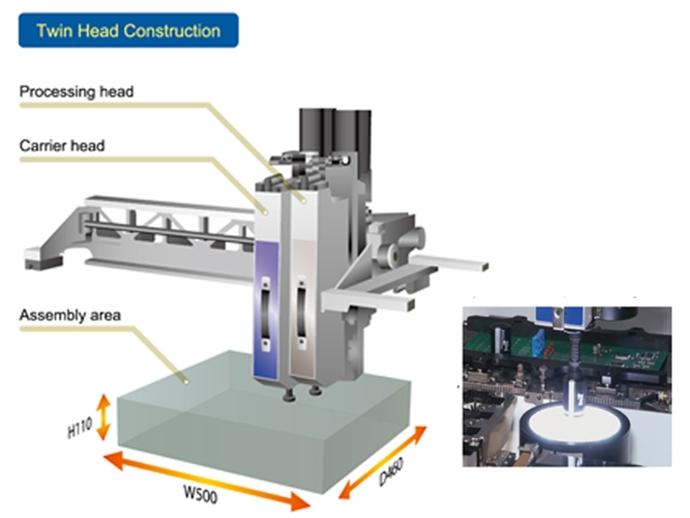

Faster and more accurate (twin head)

Vision processing to maintain high precision assembly

What's required for assembly is not robot positioning or repeatability accuracy, but assembly accuracy for the target work.

SmartFAB is equipped as standard with a base camera and robot camera to check the position of work and perform the high speed and high accuracy correction

needed to assemble with precision down to ±50 μm (3σ)*.

*Measured under conditions at Fuji

Cartesian robot capable of high speed and high accuracy

With a wide and clear assembly area, the SmartFAB robot can transport work and perform accurate assembly right across the movement region.

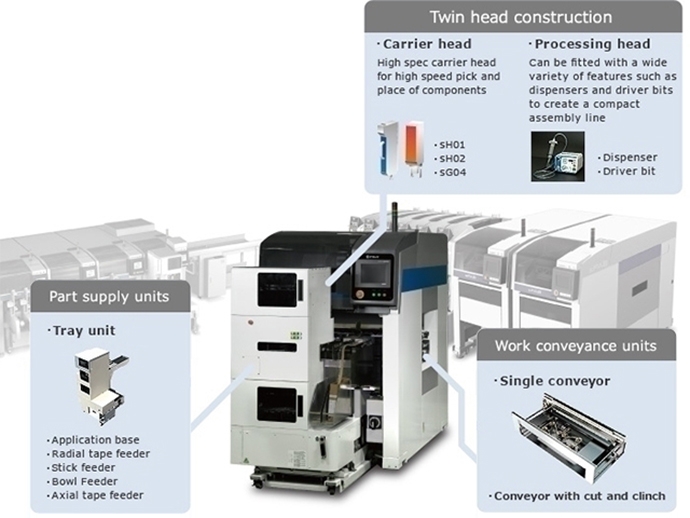

Twin head construction

Both a carrier head and a processing head can be set on the XY robot

The assembly area is an expansive 110 mm high

Both heads have an independent vertical axis and can work in tandem with each other

Faster and easier (modular)

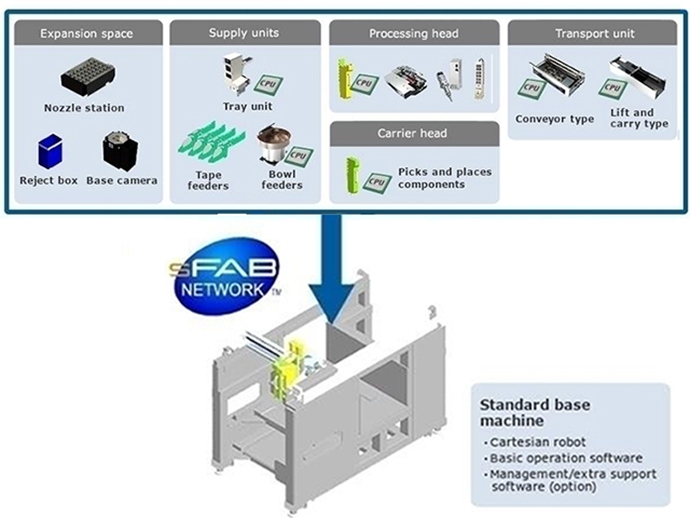

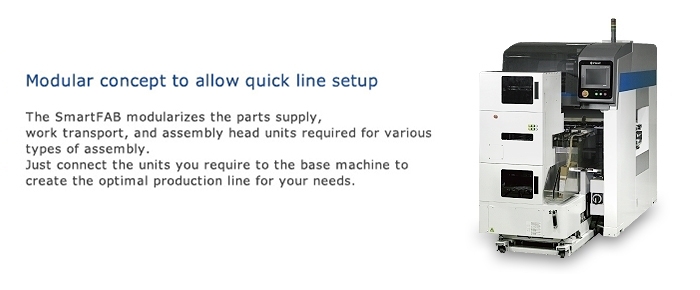

Modular concept to allow quick line setup

The SmartFAB modularizes the parts supply, work transport, and assembly head units required for various types of assembly. Just connect the units you require to the base machine to create the optimal production line for your needs.

Compared to lines created with dedicated machines or many general purpose robots, debug and setup time is greatly reduced.

This really makes a difference when starting up new lines or changing products and allows you to get the maximum out of your investment.

Unit lineup

Each unit is intelligent and fully independent

Units interact with the machine base continuously as processes are performed

By conforming to the open interface, customers can make and attach their own units