SMARTFAB

PCB Assembly (Insertion of Large Odd-form Parts)

Features

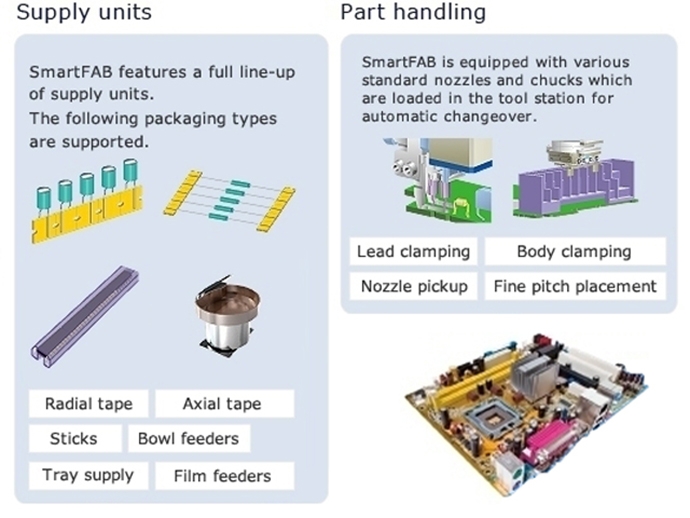

Supports Various Part and Packaging Types

Freely combine a wide range of available units to create the perfect line configuration for your production needs.

SmartFAB can handle assembly of surface mount devices, leaded parts, and large connectors all at the same machine.

PCB Assembly Example

Insertion of 2 types of radial tape parts and 2 types of large odd-form parts

Different part handling units for various insertion parts

Tools for multiple parts are loaded in the tool changer and switched automatically

Specifications

| Parts that can be mounted/assembled | Axial and radial leaded parts, DIP parts*1, odd-form parts*2 | |

|---|---|---|

| PCB size (W x L) |

48×48mm~435×500mm(single conveyor) 48×48mm~410×340mm(with cut and clinch unit) |

|

| Panel thickness | 0.4~2.0mm | |

| Part types | Axial leaded parts (under development) |

Insertion pitch: Changeable (up to 15mm) Part packaging: Ammo pack, reel (tape width: 52mm) |

| Radial leaded parts |

Insertion pitch:2.5/2.5×2/5mm Lead diameter: 0.4 to 0.6mm *3 Part packaging: Ammo pack, reel(tape width: 18mm Tape indexing pitch: 12.7 / 15mm) |

|

| DIP / odd-form parts |

Maximum part size:160 x 160 mm or 226.3 mm diagonal (when using sH02 head) Parts supply : Stick, tray, tape |

|

| Part insertion angle | Any can be supported (specified in increments of 0.001 degrees) | |

| Options |

Pins / leads check Part presence check Part insertion check Insertion placement Conveyor with cut and clinch function Backup pins Reject parts conveyor Production information viewer Simple verification |

|

*1 DIP (dual in-line package): Parts with leads on the left and right.

*2 Odd-form parts: Parts other than axial, radial, or DIP parts which are inserted into panels.

*3 Please inquire with your Fuji representative about other parts.

*Contact Fuji or sales agents for specific operating conditions and detailed specifications.