AIMEX III ACCESSORIES

Accessories

Auto Backup Pin Function

Pins are automatically positioned, checked and fine-adjusted, reducing the time required for changeover.

Panel Height Detection

Panel warpage is detected automatically so that even very small parts can be placed with extremely high accuracy.

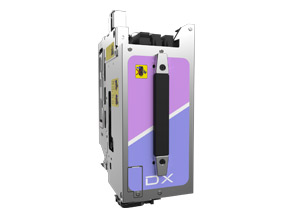

DynaHead

The AIMEX III offers dynamic exchange during production to the best tool for the job. Borderless production is made possible using the DynaHead to dynamically exchange between 12-nozzle, 4-nozzle and single nozzle tools. The DynaHead also supports specialty nozzles and mechanical chucks.

V12 Head

High-speed, 12 nozzle head, on-board vision processing

26,000 cph

G04F Head

High-speed, high accuracy, all-purpose 4 nozzle head

25um accuracy

7,500 cph

H02F Head

High-speed, high accuracy 2 nozzle head

1608 to 74mm x 74mm

25um accuracy

6,700 cph

H01 Head

High accuracy, single nozzle head

1608mm to 74mm x 74mm, max height 25.4 mm

30um accuracy

4,200 cph

OF Head

Odd-form/insertion parts head, 1 nozzle or claw

1608 to 74mm x 74mm

50um accuracy

3,000 cph

Tray Unit LT

The Tray Unit LT is equipped with (2) independently operated magazines, each magazine can accommodate up to (12) drawers and (2) JEDEC style trays each for a total of up to 48 unique part numbers.

Operating in a high volume environment, the two magazines can be set with duplicate set-ups allowing the machine to alternate when a part is exhausted and enabling non-stop production.

Operating in a high mix environment, the (2) independent magazines can be set-up for different job allowing the machine to operate off one while the

other is in set-up, eliminating change-over time.

Dip Flux Unit Plus

Supports paste and flux

Auto material depth setting, perfect for use with your PoP applications

Nexim Software

Our flexible solution integrates seamlessly with your production environment and boosts productivity with wizard and macro-based automation.

Feeder Inspection Station

The Fuji Intelligent Feeder Inspection station is used to check and adjust the condition of the feeders in order to realize stable parts supply and high accuracy placements.

Intelligent Feeders

Motor driven

Same feeder for paper or plastic

Splice detection

Nozzle Stations

Quick change nozzle supply system

Feeder Pallets

M3 pallet holds 20 8mm feeders (30 8mm feeder using Hexa Feeders)

M6 pallet holds 45 8mm feeders (67 8mm feeders using Hexa Feeders)

Auto Head Cleaner

Our Auto Head Cleaner saves time and frees staff for other responsibilities. One of the key features of the NXT is that the heads can be removed in seconds. The auto head cleaner takes full advantage of this by utilizing spare heads to run production while heads can be cleaned with no disruption to production.

Auto Nozzle Cleaner II

Our Auto Nozzle Cleaner II is powerful enough to clean grime sticking to the inside of nozzles! It's clean and ecological as it only uses water and compressed air.

Coplanarity Sensor

This option tests the coplanarity of the leads and bumps. In addition to lead coplanarity, this sensor can check bump coplanarity by measuring 3D shapes.

Tray Feeder - M/L

Perfect for supplying two and four inch tray parts.

Additional Accessories

- Calibration Unit for Optimizing Load on Parts

- Hybrid Panel Support

- H04S Head - High-Speed, Medium-Sized Head

- G04Q Head - High Accuracy Head for PoP and More

- H08M Head - High-Speed, Multi-Purpose Head

- Custom Nozzles and Mechanical Chucks

- Support for Various Types of Part Supply Packaging (W4, W88, W108)

- Multi Job Line Balancer

- Maintenance Tools

- Group Device Function

- Reel Holder

- Main Conveyor

- Mark Camera

- Tray Verification Function (RFID)

- VPDplus Auto Shape Generator

- VPDplus

- Feeder Adjustment Jig

- Vibratory Stick Feeder

- Feeder Offline Verification Kit

- VUF Brush Unit Feeder Type

- Offline Head Cleaner

- Station Type Brush Unit

- Single Vibratory Stick Unit